FDV-2 Fuel

Drain Valve Kits

Exclusive Distributor for Storehouse

Improved Sumping

This installation holds the fuel cell sump area in the cavity allowing for a more thorough sump.

Extra Protection

The kit protects the fragile rubber drain nipple from weather and wear and tear.

Clean Look

The valve installs to a compact low-profile look that covers unsightly openings in the wing.

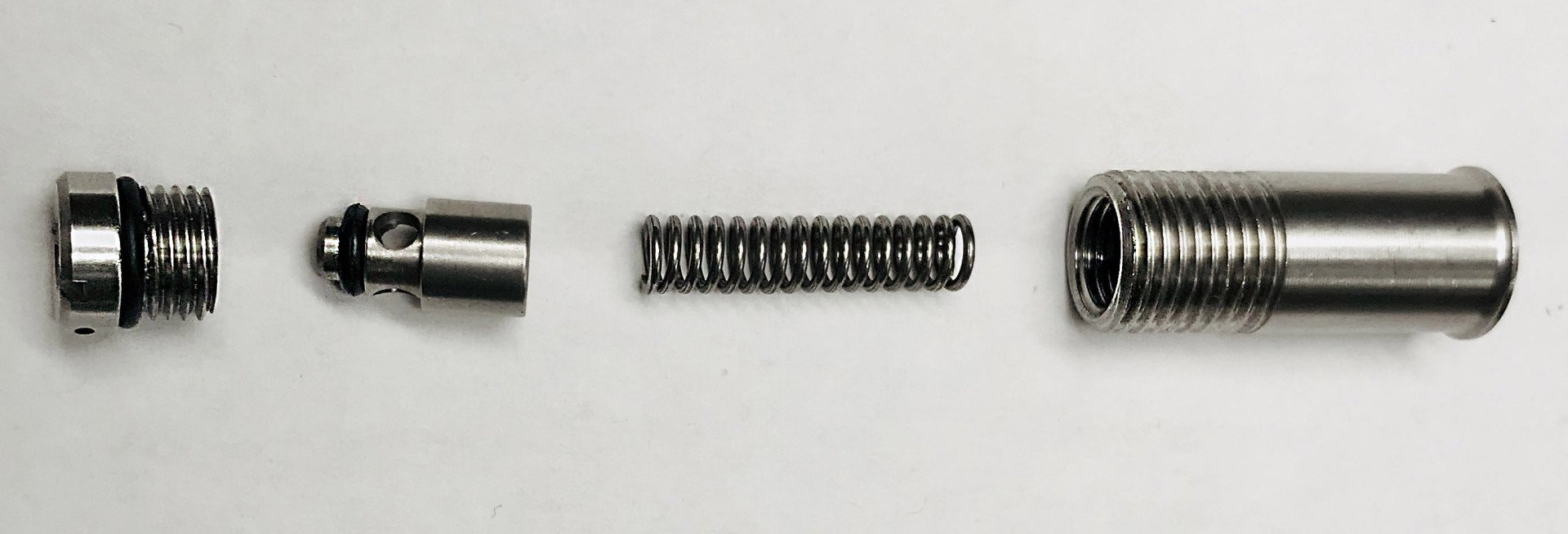

Durable

The valve is made of stainless steel and is assembled with Viton o-rings for long life.

Easier Maintenance

Once installed, you can drain the cell, clean the valve, or change the standard o-ring from under the wing without having to remove the valve. Approved replacement o-rings include:

Nitile MS29513-006 & -010 or

Fluorosilicone MS25988-1-006 & -010 or

Viton M83248-01-006 & 010.

Operation

The valve is pin actuated which also saves on wear and tear. When sumping our valves we suggest using the Jeppesen fuel tester because it is very sturdy and has a bronze rod for the pin that can be trimmed to length.

FAA Approved

Certified to meet TSO-C76b and STC’d for installation on all Beechcraft, Piper PA-23, and Cessna 100 & 200 series aircraft with bladder type fuel cells.

Recommended

By owners, aircraft associations, IA & A&P’s

Beechcraft Kit - 720B

Beechcraft Photos

The original valves have problems. For years mechanics replaced the flat seal on the valve. This process weakened the brass cap and rivet that held the valve together. Consequently, valves began to fall apart. The manufacturer stopped selling the flat seal and now sells only new valves. So every time the original valve goes bad it has to be replaced and that means undoing the hard to get to hose clamp and wrangling the old valve out and another one back in. That's a lot of wear and tear on the rubber drain nipple. Our solution is the FDV2.

Approved Model Listing:

| Model | Serial Number Applicability |

|---|---|

| 35-33 through G33 | CD-1 thru CD-1304 (except CD-982) |

| 35-C33A through F33A | CE-1 & after |

| E33C | CJ-1 thru CJ-25 |

| F33C | CJ-26 & after |

| 35 through V35B-TC | D-1 & after |

| 36, A36 & G36 | E-1 & after |

| A36TC | EA-1 thru EA-272 (except EA-242) |

| B50 & C50 | CH-12 thru CH-360 |

| D50 through D50C | DH-1 thru DH-300 |

| F50 | FH-71 thru FH-96, FH-94 |

| G50 | GH-94, GH-97 thru GH-119 |

| H50 | HH-120 thru HH-149 |

| D50E | DH-301 thru DH-347 |

| E50 | EH-1 thru EH-70 |

| J50 | JH-150 thru JH-176 |

| 95 through E95 | TD-2 thru TD721 |

| 95-55 through 95-B55A | TC-1 & after (except TC-350 & TC-1393 thru TC-1396 & TC-1402) |

| 95-C55 through E55A | TC-350, TE-1 & after (except TE-50) |

| 56TC & A56TC | TG-2 thru TG-94 |

| 58, 58A & G58 | TH-1 & after |

| 58P & 58PA | TJ-3 & after |

| 58TC & 58TCA | TK-1 & after |

| 60, A60 & B60 | P-4 & after |

| 65 & A65 | LC-1 thru LC-335 |

| 70 | LB-1 thru LB-35 |

| 65-80, 65-A80, & 65-B80 | LD-1 thru LD-511 |

| 65-88 | LP-1 thru LP-47 except LP-27 & LP-29 |

| 65-90 through C90GT | LJ-1 & after |

| E90 | LW-1 & after |

View PDF list, click here

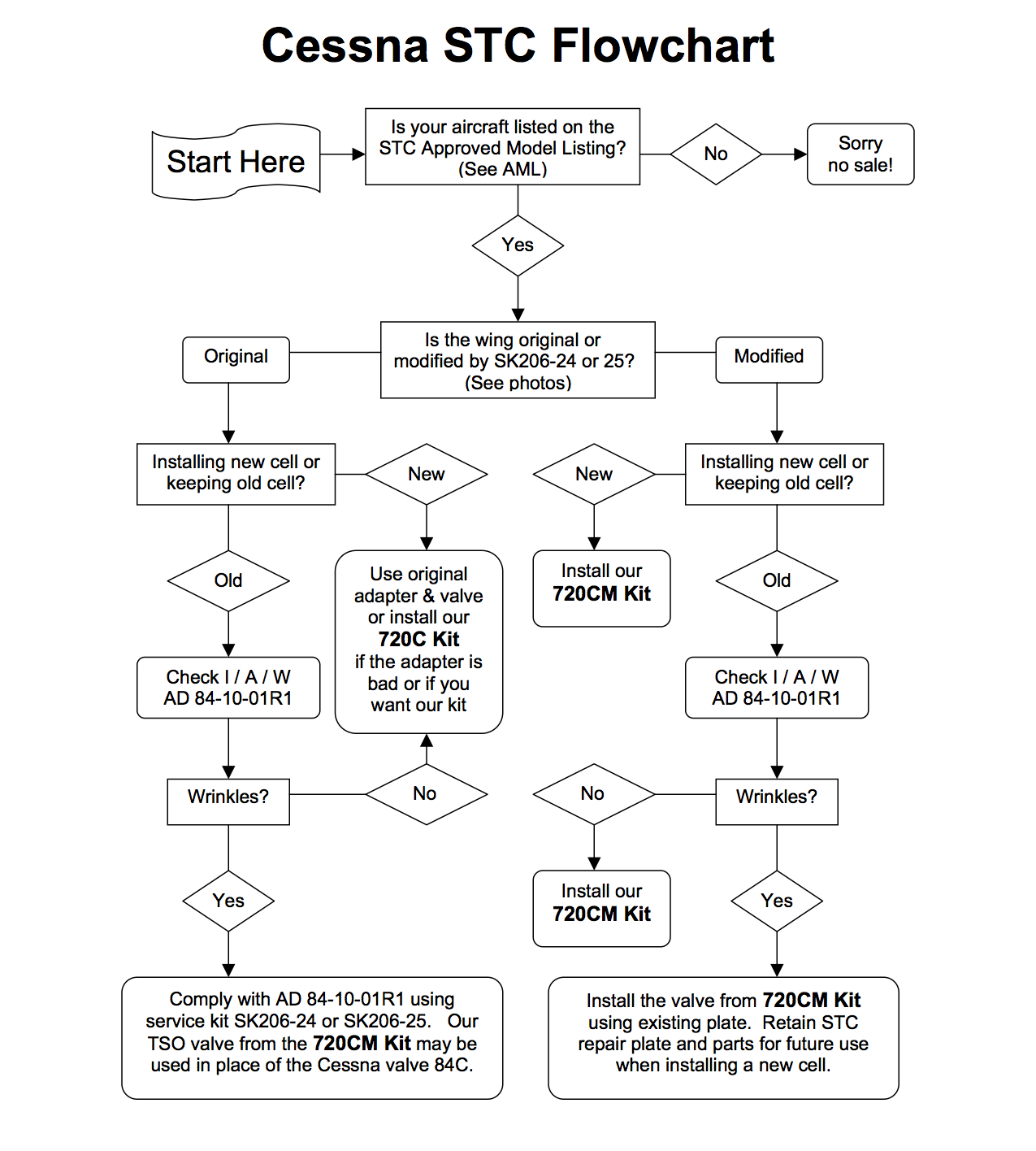

Cessna Kits - 720C & 720CM

Cessna 100-200 Series w/ Fuel Bladders

Durability

Stainless steel construction.

FAA approvals

TSO C76b - FAA standard for fuel drain valves

STC SA01380CH - Eligible for installation on aircraft with for original wings and wings modified by Cessna Service Kits SK206-XX as an alternate means of compliance for AD84-10-01R1.

View flowchart below to determine applicable kit number.

STC eligibility listings below:

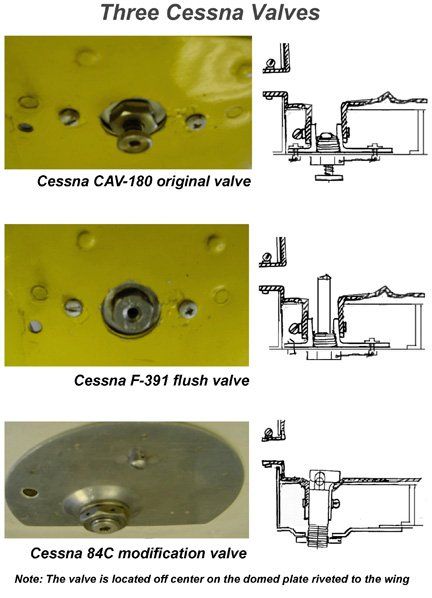

View photos of Cessna original & modified valves:

Less hassle

If your wing has been modified by any of the kits SK206-xx and you are installing a new cell, the AD requires the installation of service kit SK206-27 or -28 in accordance with service letter SE84-9. The Cessna valve P/N 84C that was installed under the AD is made of aluminum. It corrodes and gets clogged easily so most people need a new one. To make it worse, if you want to clean the valve, you must remove it. To remove it you have to partially remove the fuel cell. Our STC makes it simple because it is approved as an alternate means of compliance for this AD and it cleans up the bottom of the wing.

Cost saving

Our kits include 2 stainless steel drain valves and the necessary hardware to do both wings for half the price.

Original - 2 Cessna adapter plates

$189 each = $366 + the valves

Modified - 2 Cessna service kits

$150 each + 2 Cessna 84C valves @ $500 each = $1300

Our kits are only $275. Discounts are available.

Simplified valve maintenance

Throw away the corroding aluminum valve from Cessna that isn't serviceable without partially removing the fuel cell. Once our stainless steel valves are installed, you can drain, clean, or change the standard o-ring from under the wing without removing the fuel cell.

Recommended by

Owners, Aircraft Associations, IA & A&P’s.

Approved Model List:

| Models | Serial Numbers |

|---|---|

| Models | 604, 614, 624, |

| 30000 through 32999, | |

| 50001 through 50911 | |

| 18050912 through 18053000, except 18052490 (1978) | |

| * 18053168 through 18053203 (1981) | |

| * only aircraft with optional wing fuel cells | |

| 182-R182 | 613, 631, 675, |

| 33000 through 34999, | |

| 51001 through 53007 | |

| 18253008 through18266590, | |

| R18200002 through R18200583 (1978) | |

| 185-A185F | 652, |

| 185-0001 through 185-1599 | |

| 18501600 through 18503683 except 18502300 (78) | |

| * 18504139 through 18504448 (1981 - 85) | |

| * only aircraft with optional wing fuel cells installed | |

| 188-T188C | 678T, 188-0446 through 188-0572, |

| 18800573 through 18803973 | |

| * T18802839, T18803307T, T18803308T, | |

| * T18803325T through T18803974T | |

| * only aircraft with optional wing fuel cells installed | |

| 205 | 641, 205-0001 through 205-0577 |

| 206 | 206-0001 through 206-0275 |

| U206-0276 through U20604649 except U20602589 | |

| P206-0001 through P206-0603, | |

| P20600604 through P20600647 | |

| 207 | 20700001 through 20700788 (1969-1984) |

| 210-T210F | 616, 618, 57001 through 57575, |

| 21057576 through 21058818 except 21058140 |

View PDF list, click here

Piper PA-23 Kit - 720P

Piper PA-23 Series

For years, the FAA has tried to resolve the sometimes-exaggerated issue of trapped water in the Piper PA-23 series fuel system. Many believe, as we do, that maintenance of the gaskets and cap seals in addition to proper sumping eliminates the main source of these problems. The safety record of these aircraft shows that, if properly maintained, there really isn't a problem. However, it is proven trapped water can and does occur at altitudes other than level or near level. This concerns the rule makers and so there is a Notice of Proposed Rule Making for a possible Airworthiness Directive requiring corrective action. Two solutions have been offered.

First, a return of a rescinded AD with a slight twist. AD 90-23-18 R1 originally called for cementing a rubber wedge inside the inboard aft corner of each fuel cell. The result was a corner that trapped more water than a normal one. This time the wedge is to be installed outside the cell in the same corner. There are two basic problems with this. The wedge displaces some of the space for the fuel cell creating a wrinkle in the vertical edge of the corner. Chaffing and flexing will result in leaks down the road. The other problem is that it still doesn't get the water out of the system at the normal collecting point.

The second solution would be to install a nipple and flush drain valve at the low point. Almost all other aircraft have this feature and it works! Both solutions require the cell to be removed or nearly so for installation. The proposed costs are nearly the same. So if you were required to comply, which one would you prefer?

We acquired this STC for installing drain valves in 1998 and have upgraded it to use our popular stainless steel valve. Now you can purchase the STC kit and have the fuel cell modified or replaced all at one facility.

Benefits include:

Durability

Stainless steel construction.

FAA approvals

TSO - C76b

STC - SA01110CH

STC eligibility listings below

Improved sumping

A drain valve is installed at the low point in the inboard aft corner of the fuel cell allowing for a more thorough sump.

Clean Look

A large stainless steel washer supports the installation and protects the wing skin.

Simple maintenance

Once installed, you can drain the cell, clean the valve, or change the standard o-ring without removing the valve and disturbing the fuel cell.

Recommended by

Owners, Piper & Apache Associations, IA & A&P’s.

Piper PA-23 Photos

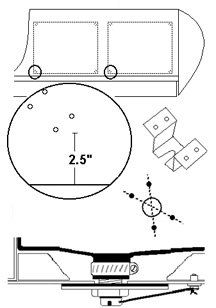

Installation

The fuel cell is removed and the bottom inboard aft attach point is removed from the fuel cell. Then a rubber drain nipple is vulcanized into the same location on the fuel cell. The wing is then modified by drilling out the four rivets that hold the corresponding attach bracket to the lower wing skin in a diagonal pattern. The bracket is removed and discarded. Next the center of the hole where the valve will pass through the skin is located by marking crossing lines from one rivet hole to the other. The valve hole and a small hole adjacent to it are drilled. A rivnut and fillister screw are installed in the small hole. The fuel cell with the valve hose clamped in place is inserted into the cavity. The valve drops through the valve hole and is secured with a rubber spacer, stainless steel washer, drilled check nut and safety wired to the fillister head screw.

Approved Model List:

| Models | Serial Numbers |

|---|---|

| PA-23-150 | 23-1 thru 23-1182 (except 23-1177) |

| -160 | 23-1177, 23-1183 thru 23-2046 |

| -235 | 27-505 thru 27-622 |

| -250 | 27-1 thru 4916, 27-7304917 thru 27-7554168, 27-7654001 and up |

| -250E | 27-1 thru 4916, 27-7304917 thru 27-7554168 |

View PDF list, click here

Share On: